The turbine is considered to be the most important component of dental handpieces. This is due to the fact that it actually does all of the work within the dental instrument.

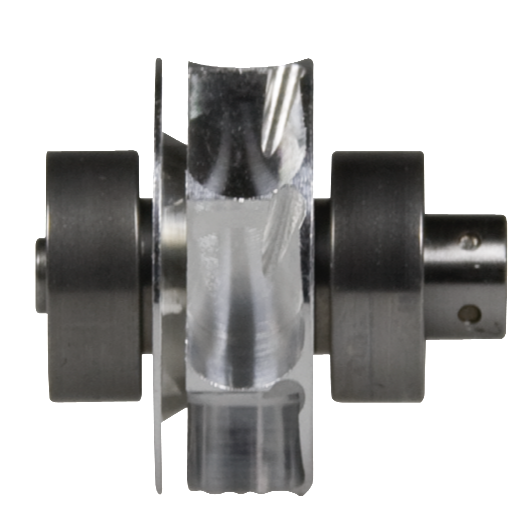

On average, the turbine includes approximately ten different components.

These include the spindle, chuck, impeller, front bearing, back bearing, O-rings, washers, and the slinger.

If your dental handpiece is not functioning appropriately, it usually means that there is an issue with one or more of the components that make up the dental turbine. Find out the most common culprits behind turbine failure and how to replace turbines.

Problems with the Bearings

In most instances, problems with the bearings cause dental turbine failure. There are several reasons why bearing problems are the most common cause of the turbine to fail within dental handpieces.

These include high levels of air pressure, the exposure to very high temperatures during the sterilization process, the accumulation of debris, load stress, a bur that is not seated properly, cheap ball bearings, and water from the air storage unit that is attached to the compressor.

If you have an issue with your dental handpieces, you should start by evaluating the bearings to determine if that is the issue.

Cold Sterilization

Cold sterilization or immersion as it’s related to in the dental industry is not appropriate and not recommended for dental handpieces. Use of cold chemical sterilization of handpieces will in fact damage the handpiece.

After steam sterilization it is important not to force cool the handpiece by running cold water over it. The rapid temperature change will damage the delicate ball bearings. To avoid needing to force cool your handpieces you should always have enough handpieces to allow them to cool to room temperature before use.

Lubrication

It is imperative that the handpiece be lubricated after every use and before sterilization. You may wish to print our lubrication guidelines.

For maximum turbine life, you may want to lubricate the chuck once weekly.

The lubrication helps to ensure that debris that finds its way in or near the turbine is flushed out so that it does not harm the manner in which it operates.

The Burs

Many practitioners have attempted to operate dental handpieces without the burs in place after lubrication. This could result in immediate damage to a couple of the different components; particularly the chuck and/or spindle. The next issue associated with burs is using those that are not the right type for the dental handpiece or inexpensively produced burs.

The proper burs must be used at all times due to the massive amount of revolutions that occur each minute. If the damaged or bent burs are used, the bearings will crumble under pressure and result in the failure of the chuck in the dental turbine.

This – in turn – can lead to complete dental turbine failure.

We Can Help

If your dental handpieces are not functioning appropriately, we can help. We here at Hughes Dental will inspect and repair your dental handpieces at the most competitive prices. We initiate the process by evaluating the turbine within the handpiece. We will only do what is necessary, when it is necessary. Additionally, we perform standard maintenance on dental handpieces.

If your dental instruments are operating in a less-than-favorable manner, simply contact us today for assistance. You may call the following number to get started:

800-773-0800